Production line refers to the production process of converting raw materials into products through continuous workstations. In this process, any problem in steps will affect the entire production process. Thus, equipment used in production lines requires extensive testing to ensure quality and efficiency. One key tool for production line testing is the antenna test.

Antennas are important devices for wireless signal radiation and reception, and their good performance will affect the overall performance of the equipment. Therefore, conducting antenna testing on equipment can help identify potential issues and prevent accidents on the production line. That’s why antenna testing on the production line plays such a significant role for manufacturers.

Projects of Production Line Testing

There are many projects for which the production line test is used, which proves to be highly effective. Three main areas include:

1. Performance Testing

Performance testing evaluates the functionality and efficiency of equipment and products on the production line. It ensures antenna parameters such as gain, efficiency, and radiation patterns meet standards. This confirms that the antenna can transmit and receive signals as intended over the specified ranges.

2. Quality Testing

Quality testing tests the qualification of different batches of products, which can help detect problems as soon as possible, reducing economic losses and preventing problematic products from entering the market. Ensuring product quality is crucial as it relates to brand image.

3. Safety Testing

Safety testing verifies that the equipment on the production line complies with all regulatory requirements for the product category and targeted markets. It can prevent accidents and injuries on the production line and ensure the safety of the production process. Moreover, conducting safety testing on the production line can also prevent property damage caused by equipment damage.

Advantages of Antenna Test for Production Line

Antenna measurement has significant advantages in production lines. Production line antenna testing allows continuous, automated testing of each device manufactured without slowing or interrupting the process. Its key advantages include:

1. High Efficiency and Speed

The high efficiency and speed of antenna measurement enable rapid testing of every device without decreasing the production scale. Antenna measurement systems have replaced the traditional complex testing methods, as they only require rotating the probe to complete 3D measurements of objects. This efficiency is crucial in mass production.

2. Precision and Accuracy

Automated and repetitive antenna test steps greatly improve precision and accuracy. Human errors, inconsistencies, and variability can be minimized through consistent, repeatable processes every time, making the production process more hassle-free and efficient.

3. Data Recording and Traceability

Using antenna measurement systems can help record data for each measurement process, facilitating subsequent data analysis and traceability. Moreover, problems that occur during the production process can be identified and corrected through these data, thereby controlling quality and improving equipment performance by adjusting parameters.

4. Comprehensive Testing

Antenna testing can simultaneously conduct multiple aspects of production line performance testing, such as transmission frequency and reception frequency, to test the product’s overall performance. This comprehensive testing can prevent vulnerabilities and reduce unnecessary time, effort, and cost investment.

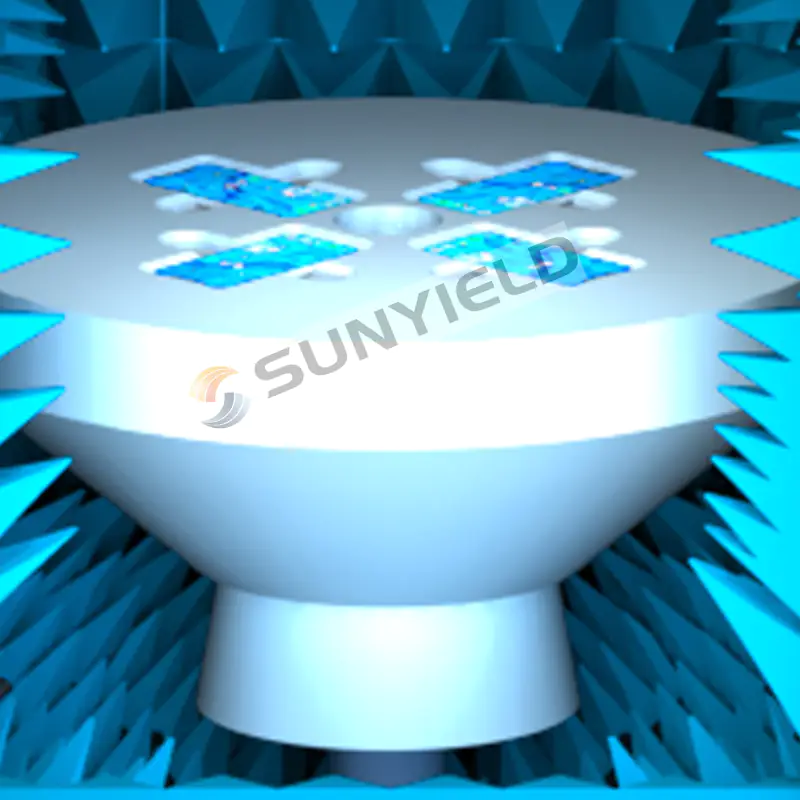

Reliable Production Line Test Equipment from Sunyield

The reputed brand Sunyield specializes in developing and manufacturing advanced antenna test systems, measuring equipment, turntables, and RF chambers. With over a decade of experience in the industry, we have extensive expertise in antenna testing technology. Our products offer powerful and comprehensive testing capabilities while maintaining flexibility, modularity, and affordability critical for production line use. The following is our equipment for the production line test:

1. OTA Testing

The information transmission between different devices needs to be achieved through interfaces. OTA testing is to evaluate the ability of the tested device to send and receive information. It can directly judge the wireless performance of the production line equipment.

Sunyield’s high-performance OTA testing solutions utilize multi-probe near-field technology to evaluate detailed antenna radiation patterns and wireless parameters. They can conduct both active and passive antenna pattern testing. In addition to supporting 2G, 3G, 4G, and 5G protocols, it supports popular wireless technologies like Wi-Fi, Bluetooth, LoRa, NB-IoT, eMTC and Zigbee.

Our extensive line of antenna test products and solutions are highly reliable and versatile. These solutions include:

1)Micro-Chamber Production Line Testing Series

Our Micro-Chamber solution offers fast OTA testing for most intelligent terminals in mass production. It supports the LF model (0.8-8GHz) and HF model (1.6-8GHz), which are suitable for devices in different frequency bands. Moreover, it utilizes a multi-probe distribution technology and also supports multi-antenna testing in non-signaling mode for faster measurement versus traditional turntables.

Sunyield also provides customized requirements for the product and ensures that users receive an economically effective product for testing the production line. The key advantages of Micro-Chamber include fast speed, small size, customizability, and low cost.

2)Mini-Chamber Antenna Measurement System

Our Mini-Chamber Antenna Measurement System is portable and supports testing small products within the frequency range from 650 MHz to 8.5 GHz. It features a compact 36 cm diameter RF-shielded room and utilizes a symmetrical distribution of probes to fully measure radiation patterns and TRP through a 180-degree rotation.

Compatible with major brand analyzers, this cost-effective solution supports active measurements of most models like 2G-4G, Wi-Fi, GPS, and Bluetooth within the frequency range of 650MHz-6 GHz as well as passive testing of 6GHz-18GHz high-frequency version through upgrades. With all these characteristics, it can be used for mobile phone and production line testing to ensure product performance.

2. SY-Radar

The SY-Radar is a vehicle-mounted millimetre wave radar measurement system used to test equipment with a frequency range of 60-64 GHz or 76-81 GHz. With a compact size of 2.0×1.3×1.95 m, it can test relevant indicators of up to 15cm in size.

The SY-Radar can measure and calibrate the targeted range and amplitude of the tested object radar, timely detect and reduce the measurement error of the radar, and achieve more accurate measurement performance. It also has supporting software that can record target amplitude and distance data in a timely manner to generate data reports.

3. SYCR Miniaturized Mobile Compact Range

Our compact SYCR range features a small, mobile design suitable for testing phased array antennas, automotive radars and their components and millimetre wave antennas. It utilizes an integrated rolled-edge reflective surface to save space compared to conventional serrated reflective surfaces.

It features a customizable multi-dimensional bearing turntable to meet users’ needs. Furthermore, its fully non-reflective microwave-shielded anechoic chamber can prevent external interference and reduce the risk of detection errors. With a mobile base, it is convenient for testing in different venues.

4. One to Multiple Antenna Testing

One to multiple antenna testing is our upgrade solution for mini-chamber and micro-chamber systems. Due to the long time required to measure mobile phones, tablets, speakers, and Bluetooth earphones in signalling mode, non-signalling testing is particularly important.

The one-to-multiple antenna testing can efficiently test 1-4 antennas simultaneously in non-signalling mode, which can save up to 50% of the test time. Our products, micro-chamber pro and mini-chamber pro solutions have both optimized the production line test in the mass production stage.

5. AudioRF-Chamber

This antenna test product provides integrated and fast OTA testing and audio measurement for intelligent terminals and audio products. Supporting a range of communication standards, it creates an optimal environment for precise audio measurement and analysis. The AudioRF-Chamber can analyze audio equipment such as speakers, microphones, and hearing devices.

The AudioRF-Chamber adopts multi-probe distribution technology and supports one-to-many tests, greatly improving testing efficiency compared to traditional testing products. Moreover, it is also compatible with mainstream instruments such as R&S, Keysight, Antitsu, Litepoint, StarPoint, etc., ensuring a wide testing range.

Conclusion

Overall, antenna testing plays an important role in verifying the performance, quality, and safety of production line antenna and wireless devices. This automated and batch-testing method greatly improves production efficiency and accuracy.

At Sunyield, our comprehensive portfolio of reliable RF measurement systems and test chambers offers the precision, speed, and customization needed for a wide range of testing applications on the production line. Our industry expertise and support further make us a trusted partner to fulfill all your antenna testing needs. Contact us to browse all of our innovative solutions.