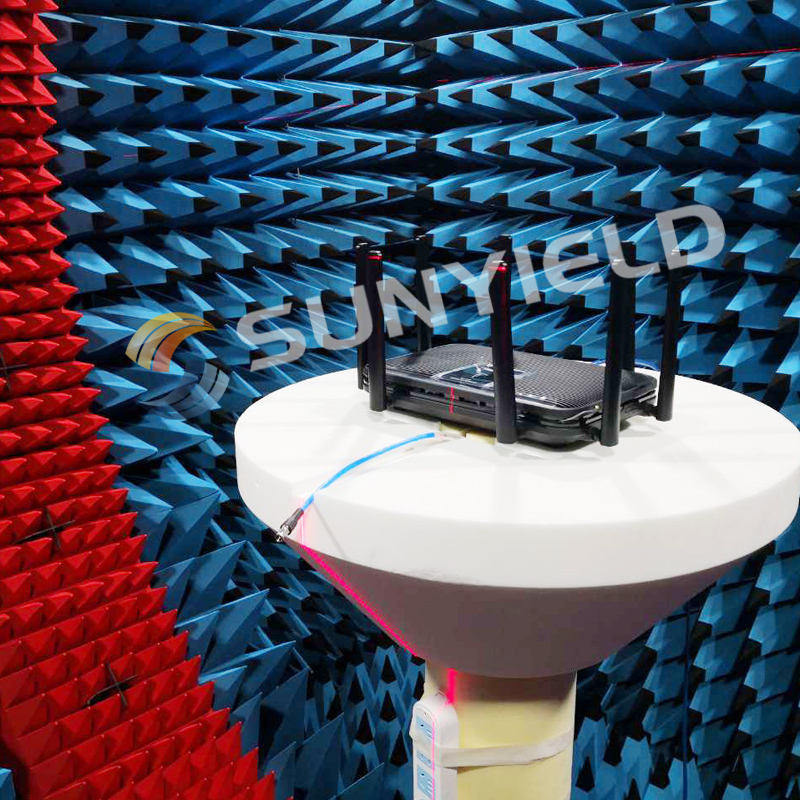

Wave-absorbing Walkway

Category Absorbing material

The microwave absorbing foam board is used as the base material, and its interior is a complete set of pyramidal wave absorber. It has excellent bearing and abrasion resistance. In addition to basic size, product of special specification and size can be customized.

Previous

Next

Description

Specification

Download

Description

Specification

Download

Get A Free Quote